Industrial robots are very dangerous. Inventory of human-machine collaboration safety control plans

2023-10-31

In the past 50 years, industrial robots have become increasingly widely used in global manufacturing. The density of robots has become an important criterion for evaluating the automation level of a country's manufacturing industry. Faced with the turning point of China's demographic dividend, Chinese workers are also facing the risk of unemployment under the policy of "machine replacement". Meanwhile, due to the level of robotics technology and integration, from an intelligent Industry 4.0 production line, manual workstations still exist, and human-machine collaboration has become the mainstream technology in Industry 4.0. Robots are the assistants of technical workers, doing repetitive "dirty and tiring work" to reduce the burden on technical workers and ensure "safe interaction" with workers.

For so many years, people have been studying the safety issues of using robots. The United States also proposes that robots in collaborative work mode must meet one of the four requirements proposed by the standard:

■ Controlled braking with safety level;

■ Manual control;

■ Speed and spacing monitoring;

■ Limit power and force.

The International Committee has drafted ISO Technical Specification (TS) 15066 as guidance for the use of this standard in collaborative work mode. In this article, we will take a look at the industrial safety control solutions in robot integration solutions.

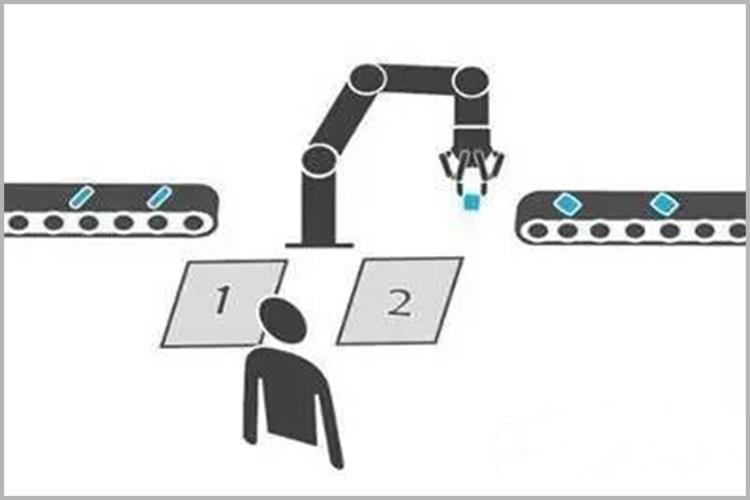

Despite the above four requirements, from the perspective of actual robot integration solutions, there are no two security control schemes for human-machine cooperation. One is an external control system scheme based on external monitoring, and the other is an internal control system scheme designed based on the robot itself.

1、 Regional monitoring plan: laser distance sensor safety light curtain

In most cases, when humans collaborate with robots, laser distance sensors are installed in the robot or its environment to monitor the entire working area of the robot. In this case, the solution is to add an area scan or light curtain that can monitor whether there are workers in the "fast operation area".

For example, the Yaskawa Motoman robot uses a controlled braking component with a safety level on its functional safety optional unit, which is located on the robot's controller. External safety laser sensors can detect whether personnel have entered the robot's operating area and notify the robot arm to slow down or stop.

Brand recommendation: Ryan's safety light curtain system for automotive equipment and personal safety solutions

For example, S4 and SFA series blind spot free safety light curtains,

Equipped with fixed, floating shielding, secondary triggering and other functions

Resolution 14mm, 21mm, 36mm

Optical axis spacing 7.5mm, 15mm, 30mm

Protection height: (number of optical axes -1) * optical axis distance

Suitable for protection areas with a length of 0-6000mm or less.

2、 Lightweight design scheme: lightweight robot body

Lightweight design is also a feasible solution for human-machine collaboration safety. By reducing the weight of the robot body, it can effectively reduce its impact on the human body, thereby ensuring the safety of human-machine collaboration.

For example, Bionic Robotics in Germany has developed a robot called "BioRob LightweightRobot (BioRob)" that can work with humans without safety sensors. Collaboration between humans and BioRob does not require any safety measures, mainly because BioRob significantly reduces the weight of its body during research and development, making it a lightweight robot. Even when working alongside humans, its impact on humans will be reduced.

3、 Intrinsically Safe Solution: Elastic Drive System

Rethink Robotics' Baxter received widespread attention after its launch in the US market in September 2012. As a versatile workshop robot, Baxter's design allows it to safely collaborate with workers in a conventional state without the need for expensive programming. Baxter is known as' intrinsic safety '.

Compared to rigid drive, elastic drive is more in line with safety requirements, just like the difference between being hit by a spring bullet and being hit by a hard object.

The patented technology that led to Baxter's success was born at the Massachusetts Institute of Technology, with the core technology being a series elastic actuator (SEA), which includes an electric motor, a gearbox, and a spring. The working method of SEA is to control the output of force by measuring the compression of the spring, and the measurement of spring compression is a force sensor.

4、 Force limited solution: motion control system

When conducting risk assessment for collaborative robots with limited force, if the robot is adjusted to a reasonable force and speed, the severity of potential damage can be reduced.

For example, Universal Robots' UR series robots weigh only 18kg, and their patented sensor technology helps them achieve power and force limiting functions. The robot knows how much force is needed to lift the load and move it. When it discovers that the required torque or force during the movement is too high, such as in a collision accident, the robot arm will safely shut off without causing injury accidents.

The above are several typical solutions to the safety problem of human-machine cooperation in industrial robots. These solutions are not independently applied in robot integration, but rather mutually integrated and supportive. In the future, with the comprehensive development of artificial intelligence, industrial robots may have more intelligent safety protection functions like intelligent robots, thereby ensuring the safety of workers in the production process.